One of the problems I have with the MendelMax 2.5 is the Z axis. The binding of the axis was and issue and the threads that were delivered with the kit had a huge wobble. I already started to modify the axis by using the “floating” setup, where the lead screws are detached from the X axis. I used this setup: Ohmeye z axis isolation This wasn’t enough and I ended up reengineering the whole Z axis setup. The last part was a support for the lead screws, so they were no longer hanging from the stepper motors. The idea is that we put bearings below the lead screws so they are supported, can rotate freely and have no side to side movement. [coupling.jpg img_20150404_134113.jpg img_20150404_134237.jpg img_20150404_135507.jpg img_20150404_135656.jpg img_20150404_135910.jpg img_20150404_140017.jpg img_20150404_143936.jpg img_20150404_144332.jpg img_20150404_144403.jpg thrust-bearings.jpg]

First we printed a simple part support part. [coupling.jpg img_20150404_134113.jpg img_20150404_134237.jpg img_20150404_135507.jpg img_20150404_135656.jpg img_20150404_135910.jpg img_20150404_140017.jpg img_20150404_143936.jpg img_20150404_144332.jpg img_20150404_144403.jpg thrust-bearings.jpg]

It holds the lower end of the bearing. [coupling.jpg img_20150404_134113.jpg img_20150404_134237.jpg img_20150404_135507.jpg img_20150404_135656.jpg img_20150404_135910.jpg img_20150404_140017.jpg img_20150404_143936.jpg img_20150404_144332.jpg img_20150404_144403.jpg thrust-bearings.jpg]

Next drill some holes to bolt it to the printer. [coupling.jpg img_20150404_134113.jpg img_20150404_134237.jpg img_20150404_135507.jpg img_20150404_135656.jpg img_20150404_135910.jpg img_20150404_140017.jpg img_20150404_143936.jpg img_20150404_144332.jpg img_20150404_144403.jpg thrust-bearings.jpg]

This now bolts to the bracket from the printer. [coupling.jpg img_20150404_134113.jpg img_20150404_134237.jpg img_20150404_135507.jpg img_20150404_135656.jpg img_20150404_135910.jpg img_20150404_140017.jpg img_20150404_143936.jpg img_20150404_144332.jpg img_20150404_144403.jpg thrust-bearings.jpg]

The whole part can now be mounted on the printer. [coupling.jpg img_20150404_134113.jpg img_20150404_134237.jpg img_20150404_135507.jpg img_20150404_135656.jpg img_20150404_135910.jpg img_20150404_140017.jpg img_20150404_143936.jpg img_20150404_144332.jpg img_20150404_144403.jpg thrust-bearings.jpg]

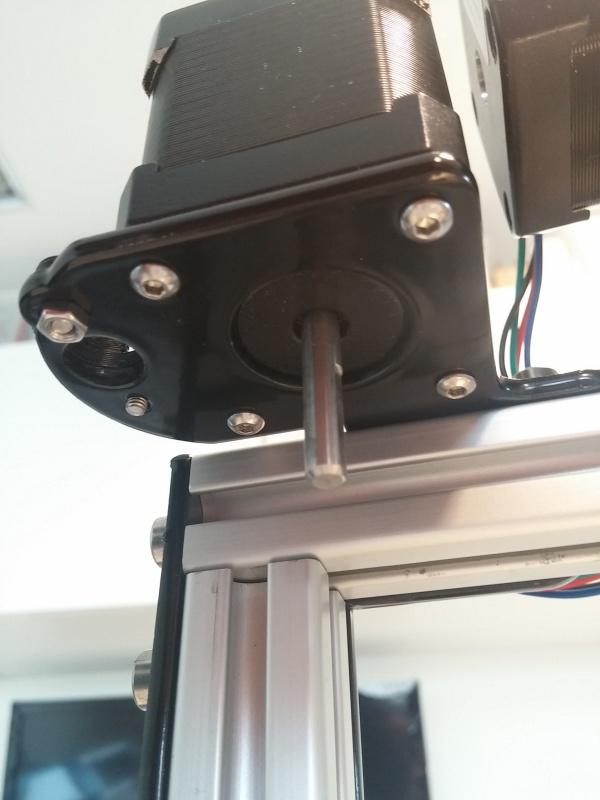

As the leadscrews will end up a bit higher, I changed the configuration of the motors, so they are now moved up above the mounting bar. [coupling.jpg img_20150404_134113.jpg img_20150404_134237.jpg img_20150404_135507.jpg img_20150404_135656.jpg img_20150404_135910.jpg img_20150404_140017.jpg img_20150404_143936.jpg img_20150404_144332.jpg img_20150404_144403.jpg thrust-bearings.jpg]

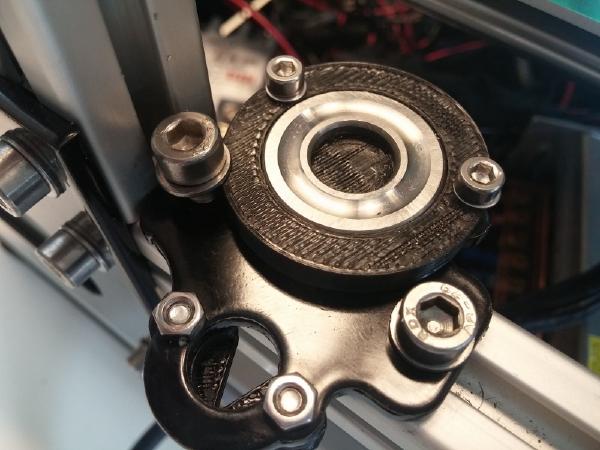

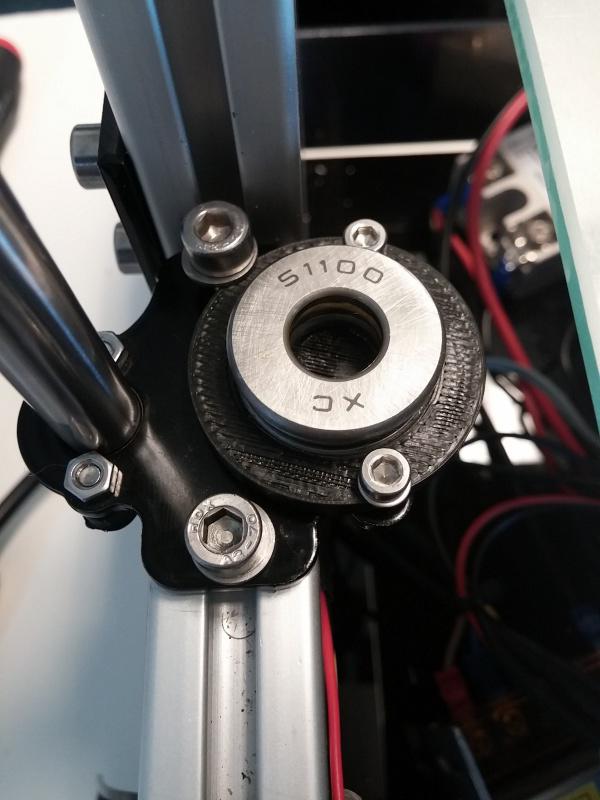

Now the to part of the bearing can be put in place. [coupling.jpg img_20150404_134113.jpg img_20150404_134237.jpg img_20150404_135507.jpg img_20150404_135656.jpg img_20150404_135910.jpg img_20150404_140017.jpg img_20150404_143936.jpg img_20150404_144332.jpg img_20150404_144403.jpg thrust-bearings.jpg]

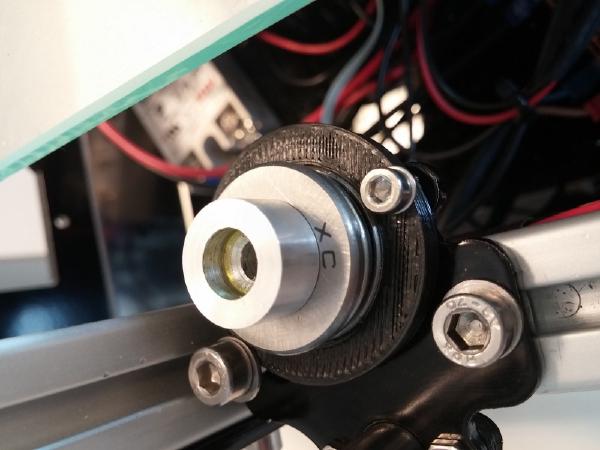

Next we milled a holder on the lathe. This slots into the hole in the bearing and has a hole on top where the lead screw slides into. [coupling.jpg img_20150404_134113.jpg img_20150404_134237.jpg img_20150404_135507.jpg img_20150404_135656.jpg img_20150404_135910.jpg img_20150404_140017.jpg img_20150404_143936.jpg img_20150404_144332.jpg img_20150404_144403.jpg thrust-bearings.jpg]

The flexible motor couplings are replaced with the ones below. [coupling.jpg img_20150404_134113.jpg img_20150404_134237.jpg img_20150404_135507.jpg img_20150404_135656.jpg img_20150404_135910.jpg img_20150404_140017.jpg img_20150404_143936.jpg img_20150404_144332.jpg img_20150404_144403.jpg thrust-bearings.jpg]

Now the new (straight) leadscrews can be put in place. [coupling.jpg img_20150404_134113.jpg img_20150404_134237.jpg img_20150404_135507.jpg img_20150404_135656.jpg img_20150404_135910.jpg img_20150404_140017.jpg img_20150404_143936.jpg img_20150404_144332.jpg img_20150404_144403.jpg thrust-bearings.jpg]

It all seems to work very well. No more side to side movements on the Z axis, movement is now very smooth. |